LOESCHE Compact Cement Grinding Plant (CCG Plant) YouTube

Mar 02, 2017· From the pioneer and pacemaker in grinding. The intelligent concept of LOESCHE''s CCG Plant enhances your flexibility during operation. You .

WhatsApp)

WhatsApp)

Mar 02, 2017· From the pioneer and pacemaker in grinding. The intelligent concept of LOESCHE''s CCG Plant enhances your flexibility during operation. You .

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with...

Manufacturer of Grinding Cement Mill, MT Fan, MAAG LGD Lateral Gear Unit and MAAG CEM drive offered by FL PRIVATE LIMITED, Chennai, Tamil Nadu. Manufacturer of Grinding Cement Mill, MT Fan, MAAG LGD Lateral Gear Unit and MAAG CEM drive offered by FL PRIVATE LIMITED, Chennai, Tamil Nadu. ... Grinding. Our range of products ...

Jan 16, 2018· JSW Cement plans to rapidly expand its production capacity with grinding mills using imported clinker, with cement mill capacities coming later. Parth Jindal, Managing Director, JSW Cement, said the c

Grinding Mill in Chennai, Tamil Nadu Get Latest Price . Business listings of Grinding Mill manufacturers, suppliers and exporters in Chennai, Tamil Nadu along with their contact details address. Find here Grinding Mill suppliers, manufacturers, wholesalers, traders with Grinding Mill prices for buying.

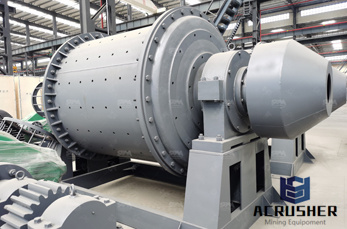

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

Find here online price details of companies selling Cement Grinding Plant. Get info of suppliers, manufacturers, exporters, traders of Cement Grinding Plant for buying in India. ... Chennai 1D/1, First Floor, Vedammal Avenue Dr. Subbrayan Nagar Main Road, Kodambakkam, ... Lm vertical cement grinding mill plant overview;

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Our OK Mill grinding solution skilfully comminutes raw material, cement and slag. You can easily adjust it to grind any feed material and produce multiple cement types in the same mill. Due to its highly effective drying performance, the OK Mill is the natural choice for grinding blended cements with one or more wet components.

In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study performed on a typical energyefficient Horomill® grinding ...

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

All these calculators are reliable, but Users need a certain experience to implement results of these calculators . Sizing equipments and mill''s optimization are the job of material suppliers and experienced engineering offices.

Manufacturer of Cement Plant Consultancy Services Cement Mill Separator offered by Jai Energy Giant Engineering Consultancy, Chennai, Tamil Nadu.

Chengalpet Grinding Unit, Uthiramerur, Kanchipuram District, Tamil Nadu ( MTPA) This grinding unit with a capacity of MTPA is located in Kanchipuram District and was commissioned in May 2009. The Plant is in close proximity to the Tamil Nadu customers, especially Chennai, which is well connected by road through NH45 and by rail through ...

MM DESPRO ENGINEERING PVT. LTD. Manufacturer and exporter of rotary air lock, cement grinding mill, parallel distributor, needle gate, sector gate, grate assy., vibrating screen, rotary feeder, double flap valve, rod gate, table feeder, air lift, open air slide, closed air slide, cement silo, raw meal silo, blending silo, cement grinding mill, material handling equipments, belt conveyor ...

Grinding Mill Ball Mill Laboratory Ball Mill Plant Machinery Mini Cement Plant Cement Blending Plant Clinker Grinding Unit Mobile Cement Bag Packaging Plant Pneumatic Bag Packaging Machine Mineral Grinding Plant

Our organization is a cement grinding unit, cement mill manufacturer supplier in India. We also offer consultancy, turnkey projects and engineering services. Our organization is a cement grinding unit, cement mill manufacturer supplier in India. We also offer consultancy, turnkey projects and engineering services.

Grinding cement in ball mills. The principle of the ball mill operation is simple: it consists of a rotating drum and grinding media (cylinders, balls etc). The material is placed into the drum which starts rotating. The grinding media and the substance both come in circular motion and at a certain point drop from the walls the bottom of the drum.

For raw grinding with relatively dry raw materials, the combination of the roller press and V separator is a viable alternative with far lower mill fan power. Cement grinding. For cement grinding, the technology development away from ball mills has taken a different route.

Approx. Rs Lakh / Unit Get Latest Price We are engaged in Ball Mills manufacture and supply in a wide assortment of variations that are used for grinding the crushed materials. These are commonly used for producing powder from fertilizers, cement, silicates, glass ceramics and many more. These are available as grate type as well as overfall type based on ways of discharge.

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of .

The segmentation of grinding and milling systems. Module 2 – Ball mills. This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process. * Mechanical description of the different types of mills. * Ball mill grinding equations and dimensioning. * Mill internals, media, liners and ...

The "Mill audit expert" software, also called MAE, is used to evaluate a cement ball mill and its separator. By completing only the "Fill the form" sheet, the other sheets of the program will be automatically calculated. Last but not least, all calculations will automatically generate a complete report on the situation of the grinding ...

WhatsApp)

WhatsApp)