Ball Mill Hydrostatic Slide Shoe Bearing | Bearing ...

Ball Mill Hydrostatic Slide Shoe Bearing Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Curso

WhatsApp)

WhatsApp)

Ball Mill Hydrostatic Slide Shoe Bearing Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Curso

Dubai Bangladesh Cement Mills Ltd. A concern of A Hossain Group. Dubai Bangladesh Cement Mills Limited is one of the leading innovative cement manufacturers in Bangladesh. Dubai Bangladesh Cement Mills Limited started commercial production on 18th February 2003 with having a production capacity of million tons per annum.

COPPER MOUNTAIN: OVERVIEW ON THE GRINDING MILLS AND THEIR DUAL PINION MILL DRIVES ABSTRACT This paper will first give a short overview of the Copper Mountain project in British Columbia, which just has started commercial operation earlier .

slide shoe bearing replacement on a cement mill. Slide shoe bearing pdf The drive cement ball mill shoe bearing operation 16 Sep 2013 ball mill slide shoe bearing pdf ball mill operation and maintainance slideMills with circumferential and sliding shoe bearing assemblies provide the following. slide shoe bearing material Sliding shoe bearing assembly, slide ring and axial guide.

slide shoe bearing material Sliding shoe bearing assembly, slide ring and axial guide. slide shoe bearing cement mill come with combined trunnion and slide shoe bearings. slide shoe bearing pdf This is primarily due to the support bearing design and the mill ball mills for the cement industry are available in different

ring erection and allows for a simple and economic founda tion design. These shoes fit! The slide shoes are coated with a special white metal with good tempe rature Compact and efficient! Tube mill with slide shoes and INTEGRAL DRIVE Fitting shoes. KHD Humboldt Wedag mills are not only becoming increasingly spacesaving and compact, they are also

FAST''S® Gear Couplings Lubricant Capacity FAST''S vs. Oring Style Why Is The Design Unique? The AllMetal End Ring, used exclusively in FAST''S couplings, eliminates the need for any type of perishable lube seal (Orings, lip seals, cork gaskets, etc.). The end ring .

By this summer, a grinding mill that is bigger around than a Boeing 747 will turn chunks of copper ore into gravelsized bits for smelting and refining. The largest ring gear will make it happen

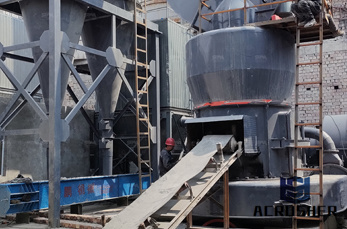

• cement industry: Nghi Son, Vietnam, 1998,Guangzhou, China, 2005. Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The development was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair

Within 20 seconds of entering the pellet mill, feed goes from an airdry (about 1012 percent moisture) condition at ambient temperature, to 1516 percent moisture at 8090°C. During subsequent compression and extrusion through holes in a ring'' die, friction further increases feed temperature to nearly 92°C.

Customers in the pulp and paper and cement manufacturing industries learned firsthand the benefits of our Cardox CO ² high pressure blockage clearing system. Dispatched to their sites, our technicians prepared an action plan for clearing the stubborn ring build up inside the rotary kilns shown here.

Jun 25, 2016· Report about the repairation of the Raw mill Slide Ring and shell (Modification) 1. Repairing the wears and cracks in the Raw Mill Tyre and shell MBCC ASEC Castolin 2013 Eng. Moaaz Emad Gaber

conveyor Next Raw mix kiln cooling Back preheating clinker storage at the plant Raw mill THE CEMENT MANUFACTURING PROCESS : The clinker and the gypsum are very finely ground giving a "pure cement". Other secondary additives and cementitious materials can also be added to make a blended cement. 1.

Overlays (either structural or nonstructural) make up a large portion of the roadway paving done degree of surface preparation for an overlay is dependent on the condition and type of the existing pavement. Generally, the existing pavement should be structurally sound, level, clean and capable of bonding to the overlay.

May 25, 2016· Ball Mill || Principle construction Working and use of Ball Mill || attrition and impact Duration: 9:26. Gold full movie of Akshye Kumar 2018 22,640 views

Abstract: In the process of selecting a suitable motor for a cement mill, there are several issues to consider that, for the purpose of analysis, can be grouped into two distinct categories. The first category is the technical analysis, which is based on engineering considerations that evaluate the merits of either a synchronous or a slipring induction motor installation.

An increase in clinker AR (also sometimes written as A/F) means there will be proportionally more aluminate and less ferrite in the clinker. In ordinary Portland cement clinker, the AR is usually between 1 and 4. The above three parameters are those most commonly used.

We greatly appreciate your suggestions about our products and services. Please contact us use email if you have any suggestions about our products and services

MILL DRIVES FOR CEMENT INDUSTRY NATHAN SCHACHTER CIMENTEC ENGINEERING LTD. October 29, 2006 2 A. Ball Mill Drives SINGLE MOTOR DRIVES • Ring gear and pinion with lowspeed synchronous motor and air clutch • Ring gear and pinion with .

patent and started selling an improved version of this mill all over the world. For the cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

CEMENT MILLB OUTLET BEARING TEMP HIGH. Respected seniors. we have cement mill with roller press capacity 165tph. we have slide shoe bearing on our mill outlet and inlet during summer season we facing difficulties to control our mill outlet bearing temp as it raised upto 79 degree celcius and tripped mill. our bearing materaial is white metal and our lubrication oil 320. our lubrication ...

Model: All Glock (Except G42/43), CZ, MP, VP9, Sig P320 Service: CNC Mill Slide To Accept Genuine Trijicon RMR RM06 (Type 2) Optic: Genuine Trijicon RMR Included Finish: Cerakote Or Black Nitride Other: Sights In Drop Down Are For GLOCK Only. CZ, MP, And Sig P320 Sights Are 70 Can be Added In Products/Custom Price. We mill precision pockets for your optic!

Bladed junk mill (left), conebuster mill (middle), and cement mill (right). Bladed junk mills. Bladed junk mills are dressed with highquality tungsten carbide to ensure optimal performance in all applications. These milling tools are suitable for all types of general junk milling, as well as for removing packers, retainers, and squeeze tools.

Our OK™ Mill grinding solution skilfully comminutes raw material, cement and slag. You can easily adjust it to grind any feed material and produce multiple cement types in the same mill. Due to its highly effective drying performance, the OK™ Mill is the natural choice for grinding blended cements with one or more wet components.

WhatsApp)

WhatsApp)