Coal Pulverizer Maintenance Improves Boiler Combustion

Mill power to ton of coal throughput. ... # coal pulverizer maintenance # coal mill operation # burner belt combustion. More Coal News "Blueprint" Your Pulverizer for Improved Performance.

WhatsApp)

WhatsApp)

Mill power to ton of coal throughput. ... # coal pulverizer maintenance # coal mill operation # burner belt combustion. More Coal News "Blueprint" Your Pulverizer for Improved Performance.

coal mill maintenance practice mining quarry crusher. Maintenance Of Coal Mill In Thermal Power Plant. China three rolls mill machine oudereninactiebe spice grinding machine made of stones from china symmons 5 12 short head cone crusher weight angle of breakage in ball mill salt crusher and grinding degroenewelvaartnl salt mining process nemosjanitorcoza crusherstone machine china ...

Coal Mill Maintenance Workshop surindernarainuja. The coal mills are very robust, and have high availabilitylow maintenance requirements. The coal mill tends to break the pellets back to the original dust. Prices / Quote. Power Generation From Coal International Energy Agency.

Four coal mill trains were used without a spare and sized to achieve 85% load on three trains. 2. A single backend flue gas train was used with one induced draft fan. Using a single fan in conjunction with preventative maintenance procedures is shown not to affect plant availability significantly.

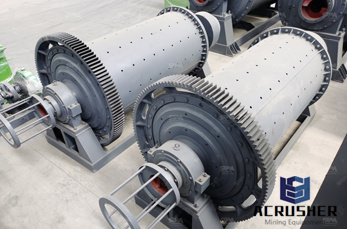

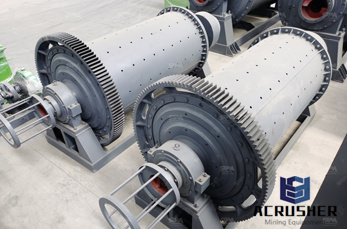

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles ...

power plants maximum requirements of fuel is a coal. The handling of this fuel is a great job. To handle the fuel,, coal, each power station is equipped with a coal handling plant. Maintenance of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job.

coal mill maintenance plan|grinding mining coal mill maintenance plan With many years of production experience, installation experience of millions of equipment units and a large amount of RD investment, our roadheader is suitable for crushing operations of various metal mines, equipped with a national patented scraper conveyor, which can ...

maintenance roller mills coal mill maintenance coal mill in cement plant coal mill. maintenance coal mill . Coal Mill Design,Used Coal Mill in Power Plant for Sale in, maintenance coal mill,Coal Mill Design In power plant, coal mill, usually vertical mill is used to grind coal into powder The best features of all the pulverisers have been incorporated, maintenance ...

Normally, the entire requirement of PA flow necessary for a particular load at the mill is initially attempted through HAD so as to ensure complete drying of the coal (especially during rainy seasons) and to raise the mill temperature at a desired point. However, there may be times during hot dry summers when the mill outlet temperature shoots up.

Coal Mill Maintenance. Detail of coal mill operation maintenance for surface coal mine facilities, coal refuse reprocessing facilities and coal mining activity facilities pulverizer wikipedia pulverizer or grinder is a mechanical device for the grinding of many different types of materials for example, a pulverizer mill is used to pulverize ...

Best Practices In Coal Mill Maintenance. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment. And they are mainly used to crush coarse minerals like gold and copper ore, metals ...

Performance Driven Maintenance Provides A Path to Achieve Results Improved 50 mesh by adjusting classifier blades. By conducting periodic Isokinetic coal sampling pulverizer performance can be tracked so that maintenance decisions are based on the truly .

Maintenance Of Coal Milling Plants. Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders compared with the ordinary ball mill it has advantages of higher capacity more convenient operation safer usage and more reliable performance coal mill i Maintenance of coal milling plants . Get Price

Coal Mill Maintenance. Detail of coal mill operation maintenance for surface coal mine facilities coal refuse reprocessing facilities and coal mining activity facilities pulverizerwikipedia pulverizer or grinder is a mechanical device for the grinding of many different types of materials for example a pulverizer mill is used to pulverize . Chat ...

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

Coal mill, gypsum mill, clay mill, etc. | Pfeiffer MPS mills Gebr. Pfeiffer MPS vertical mill from Pfeiffer is the ideal allrounder. ... wear materials and sophisticated service concepts, maintenance times of the MPS mill are reduced.

maintenance check list belt conveyor, plant,project,suppliers .. coal fired power plant etc. Zenith''s stone crusher and grinder mill works for crushing and . vertical roller mill, maintenance check list belt conveyor, . »More detailed

Maintenance Coal Mill. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Oct 07, 2019· Here, we''ll discuss effective design, operation and maintenance tips for this critical component of the coal grinding circuit and what you can do to evaluate the readiness of your coal mill dust collector. For complete recommendations on maintaining and operating coal mill dust collectors and how to reduce unscheduled maintenance, downtime and ...

Coal Mill Maintenance Coal Mill s Maintenance Work To Be Done. Coal Mill Maintenance. Maintenance must be done every day so as not to be a big problem in the future to adhere to regular maintenance work after each stop to check for loose bolts mechanical ministries must loose robust visual check before and after the host bearing lubrication ...

coal mill repairers. A semiautogenous grinding mill, or Sag mill, is responsible for grinding materials, designed to process, crush, separate, or locate precious metals from mined coal, pieces, and often requires mining equipment repair and maintenance...

Pulverizers Coal Grinding Roller Mills William''s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal mill.

Vertical Roller Mill Operation And Maintenance. Coal mill gypsum mill clay mill etc the mps mill also grinds dries calcines and classifies gypsum without any problem all in a single machine for any fineness requested and considering individual requirements the mps vertical roller mill built to last reliable and energyefficient is the optimum solution when it comes to performing several process ...

coal milling plant maintenance. coal milling plant maintenance XSM excellent mining crushing machinery products or production line design, the company is committed to Chat Free maintenance of coal mill and coal feeder

WhatsApp)

WhatsApp)