Cement mill Wikipedia

ball mill calculation data in pdf grinder. ball mill calculation data in pdf. (PDF) data for Ball Mill Design; Grinding Parts ball mill calculation in cement Crushing Plant Grinding Mill . Chat Online

WhatsApp)

WhatsApp)

ball mill calculation data in pdf grinder. ball mill calculation data in pdf. (PDF) data for Ball Mill Design; Grinding Parts ball mill calculation in cement Crushing Plant Grinding Mill . Chat Online

Ball mill spare parts: liner, grith gear, pinion, bush liner and hollow shaft View More VIEW MORE ... Industrial Kiln and Grinding Equipment Used in Cement. We can provide a wide variety of cement processing plant, including 6000t/d, 5000t/d, 3000t/d, 2500t/d, 1500t/d, and 600t/d cement .

We offer a full line of parts for rod, ball, and semiautogenous grinding mills for cement plants. Shell liners We offer many choices in design and alloys for all popular mills, ranging from traditional wave styles to step liners, classifying liners and SAG mill liners.

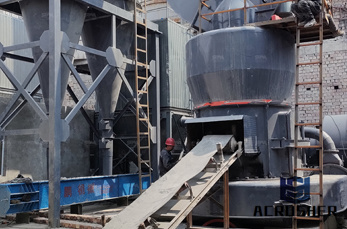

Feb 10, 2016· VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to

sections of a cement ball griding mill. Home / Products / sections of a cement ball griding mill; kassia. Questions / Comments . Get Price; PedalTheOcean . Chuck did a great job but I can t decide if I actually like the paint color or not. It s not what Ken and I had specified and I .

The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill''s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and application.

Special Price for Gold Ore Ball Mill Cement Grinding Ball – HG Product Description Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr. content. Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr. content.

Used in cement grinding production grinding parts of its various forms, there is a cylinder, cone type, ball type, etc., and roller surface is also flat, curved, convex round noodles. Applied to the grinding roller to roller grinding along the track bed in close contact with the .

Double supplies you the below cement grinding mill cement raymond mill cement roller mill cement ball mill cement MXB Coarse Powder Mill . Get Price; Cement mill notebookLinkedIn SlideShare. Jan 07 2015 · In cement grinding the mill ventilation system fulfils two important functions cooling the cement and removing the heat generated during the ...

Con grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement clinker. The advantage of Con medium is its ability to increase mill capacity because of its interlocking shape and increased density per cubic foot of grinding charge.

The order includes a MVR 6000 C6 mill for grinding slag cement and a MPS 3070 BK mill for grinding fuel. Delivery is scheduled for early 2019 and mid2019 respectively. The MVR mill will feature a total drive power of 5820kW. Get Price; Coal Ball Mill. Coal ball mill is the equipment used for grinding and drying coal with different hardness.

Ppt On Ball Mill Grinding Media In Cement Industry. Ppt on ball mill grinding media in cement industry ppt on ball mill grinding media in cement industry quality spare parts and consumables like grinding media ball mills are predominantly used machines for grinding in the cement industry although ball mills have been used for more than one hundred years the design is still being improved in

VRM vs Ball Mill for Cement Grinding Page 1 of 1. 10/2/2016· Reliability Product quality good partcicle size distribution in ball mill as we can play wtth Grinding media filling. VRM has less flexibility in controlling particle size distribution. Overall ball miil is good option for Cement mill but only has limitations for higher capacity ...

Ball mill ball milling machineball grinding machinery ball mill dry or wet process application ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and.

Cement Ball Mill is mainly used in grinding of cement finished product and materials, also to the metallurgical, chemical, electricity and other industrial and can be used to open streams, but also to the composition and the separator flow grinding ball mill has a strong adaptability of materials to production, broken rate large, easy to speed grinding fineness of the product and ...

Extensive sampling campaign was performed around the cement grinding circuit of a cement plant in Turkey, for different production types of cement, as CEM I, CEM II //, for the ...

Cement grinding with our highly efficient ball mill An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance.

Jul 18, 2016· Operation and Elements of a Closed Circuit Ball Mill System. Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber.

The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the maintenance inspection of the ball mill system. This course offers an indepth understanding of the maintenance activities, providing the precise tools to achieve optimal levels of personal performance and ...

Ball Mill,SAG/AG Mill,Rod Mill,Cement Mill. We can provide CITIC, SINOMA, NHI and other brand grinding mills, cement kilns and other equipment and spare parts for mine and cement customers around world. Language: English. ...

ball mill calculation data in pdf grinder. ball mill calculation data in pdf. (PDF) data for Ball Mill Design; Grinding Parts ball mill calculation in cement Crushing Plant Grinding Mill . Chat Online

HG is devoted to researching, developing, producing and selling crusher spare parts, mill liners, grinding media, which are widely used in Cement, Mining, Chemical Industries, and Power, etc. Our manufacturing base covers 39,000 square meters, with the standard workshop area of 21,000 square meters, annual productivity up to 30,000 metric tons.

Ball mill layout a ball mill is a have been used for cement grinding cement milling is the largest user of electric power on a cement plant ore info cement industry ...

WhatsApp)

WhatsApp)