A suitable laboratory mill for every application RETSCH

When looking for the best laboratory mill, material properties must be taken into account. We offer a suitable laboratory mill for every application!

WhatsApp)

WhatsApp)

When looking for the best laboratory mill, material properties must be taken into account. We offer a suitable laboratory mill for every application!

Get latest info on Ball Mills, suppliers, manufacturers, wholesalers, traders ... and grinding solution with Ball Mill and air classifier closed loop circuit. ... Clients can avail an incredible range of ball mill at costeffective prices. ..... These ball mills are used for the purpose of grinding the solid materials into tiny and small .

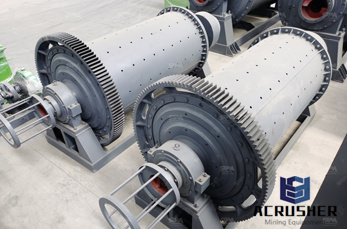

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

Equation 1 is multiplied by the factor of A multicompartment ball mill consists of two or more grate discharge ball mills in series. The same equation is used to calculate the power that each ball mill compartment should draw. The total power is the sum of the .

For this reason, LAVAL LAB offers a wide selection of highperformance mills, in various product groups, for every application and every specific need: Planetary Ball Mills, Ball Mills, Cutting and Beater Mills, Rotor Mills, Jaw Crushers, Roll Crushers, Cone Crushers, Disk Mills and Mortar Grinders.

gold ball mill grinder with flotation Froth flotation grinding mills, Copper ore ball mill process Gold Ore Crusher For selective flotation, the concentrate was reground in ball mills to produce a finer Related to Froth flotation grinding mill Get a Price gold ball mill grinder with flotation tanks Read More. Oline Chat

Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics." Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill of appreciable performance.

Metallurgical ContentOpen Circuit GrindingClosed Circuit GrindingGrinding Circuit Process Control VariablesGrinding Operating Costs The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig. 9. This singlestage circuit is chiefly employed for coarse grinding when a product finer than 65 ...

cost of small ball mill grinder circuit notes for. ball mill grinding pdf A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints,Grinding Mill Or Ball Mill Pdf miningbmw. ball mill .

cost of small ball mill grinder circuit siculocks. cost of small ball mill grinder circuit nylonwheelsin. cost of small ball mill grinder circuit paperABB Group The initial capital costs are higher than some of the direct online solutionsThe method of powering mills .

Mineral mill,ultrafine millï¼grinding mill, grinder . mill is twice than jet mill and agitation mill. . ultra fine grinding mills – Crusher South Africa Unlike other designs of media mill, agitated mill, .

Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell .

Table of ContentsBatch Ball Mill GrindingWet and Dry Open Circuit Ball MillingType of Grind with Different Amounts of Ore Charges in Wet and Dry Ball Milling Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages. The results are summarized in table 16, which shows that in both capacity and ...

Fits Bridgeport and others with a 9cog interface. 625" center bore, and " max machine pin length. Available w/ 1/2" deeper bore. "This is the most simple and functional tool. I have several different operations I perform on my mill and the table has to move a great deal up and down.

Ball Mills Autogenous Mills Grinding Circuits Open Circuit Grinding Closed Circuit, equipment Only a small amount of the supplied energy actually ... Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral, horizontal or at a small angle to the horizontal it is partially filled ...

Mar 29, 2019· How to Make a Ball Mill. Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance...

Nov 25, 2014· DIY homemade ball mill. Easy to make Made from some PVC pipe, a few castors, and electric motor, and a power supply

Small Ball mills are generally recommended not only for single stage fine grinding but also have wide application in regrind work. The Small Ball mill with its low pulp level is especially adapted to single stage grinding as evidenced by hundreds of installations throughout the world.

The ball mill equipment developed by FTM Machinery is a ball grinding machine, which uses steel balls as the grinding medium. And the ball mill grinder is mainly used for grinding cement, silicate products, new building materials, refractory materials, fertilizers, various ores and glass ceramics, etc.

China Small Ball Mill Grinder for Material China Roll . Roll Mill, Minerals Ball Mill, Mill Machine manufacturer / supplier in China, offering Small Ball Mill Grinder for Material, Mobile Mercury Mining Equipment Amalgamation Barrel for Mercury Concentrating, Hot Sale Pure Gold Mobile Amalgamation Barrel Gold Mining Equipment and so on. Read more

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

We can also buy surplus ball mills or sell on a consignment basis. From small Lab and Pilot Batch Mills to large Ball Mills, we source mills to suit your needs manufactured by Denver, , Allis Chalmers, Polysius, FL, Dominion, Hardinge, , and more. A ball mill is a cylindrical device used in grinding (or mixing) materials like ...

Working principle of 38t/h Open Circuit Cement Mill In Cement Making Machinery: When the cement mill works, motor and speed reducer transmit torque force to big and small gears of ball mill.

WhatsApp)

WhatsApp)