(PDF) Clinker grinding process and cement properties ...

Cement additives permit to reach bothe the targets. ... Clinker grinding process and cement properties improvements by additives ... agglomeration and particles sticking on the mill .

WhatsApp)

WhatsApp)

Cement additives permit to reach bothe the targets. ... Clinker grinding process and cement properties improvements by additives ... agglomeration and particles sticking on the mill .

Thanks to its grinding plants with throughputs of 2 to 1000 t/h for the cement industry and selfinert, central coalgrinding plants for hard and brown coal power stations, Loesche is the global market leader for vertical mills and turnkey grinding mills.

is employed for coal grinding mills and mills in the cement and industrial minerals industry. 2, 3, 4 or even 6 grinding roller configurations for a single grinding table can be realised. The first Type LM D modular coal grinding mills were developed in 1980 and employed for .

About us. The Cement Grinding Office, a new concept to support engineers and technicians working every day with a ball mill. In the cement industry, the ball mill is probably the Nemesis of all ...

The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses; Calculators Online

Jun 07, 2018· The OK mill has been FL''s standard cement vertical roller mill (VRM) since 1993. In 2017, FL also introduced the OK raw mill for raw material grinding, designed with the same proven ...

Visualizza il profilo di The Cement Grinding Office su LinkedIn, la più grande comunità professionale al mondo. The Cement ha indicato 10 esperienze lavorative sul suo profilo. Guarda il profilo ...

cement industry the ball mill was really an epochmaking breakthrough as for ... applications of the vertical roller mill for cement grinding are less prevalent. Read More. Cement mill . A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently...

Grinding plants Optimized mill technology. No two mills are exactly the same – and every customer has different requirements. Christian Pfeiffer designs and constructs mills and mill equipment, individually tailored to each respective production to deliver optimum results. Learn more about our grinding plants

Mar 08, 2013· re CALCULATION OF BALL MILL GRINDING EFFICIENCY. Please can anyone give me, step step by procedure on how to work out on cement ball mills to. improve it''s efficiency, optimum operation and increases output.

Raw Grinding Mill . Raw Material Conveying . Raw Meal Silo . Raw Mill Section . Raw Proportioning . Kiln. Capacity: 5000 tons/day: ... Cement Grinding Mill . Cement Mill . Cement Mill1 . Cement Mill2 . Cement Silo and Bulk Loading . Roller Press . Packing. ... Mandalay Office: No(3B),Between 65 and 66 street, Theik Pan Road, Chan Mya Thar Si ...

Mill Grinding Course. PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this twoday course.

Apr 21, 2015· Gebr. Pfeiffer MVR Roller Mills In the cement industry, MVR roller mills are used for grinding cement raw material, cement clinker, granulated blastfurnace slag, and .

Metallurgical ContentRAW CEMENT GRINDINGWET VS DRY Grinding of CementCLINKER GRINDINGCement Grinding MillsHigh Efficiency Cement Grinding Mill The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and finish grinding begin to enter the .

Apr 16, 2019· Ghacem Takoradi Cement Grinding Mill Details Parent Category: Ghana Category: Cement Industry Last Updated on 16 April 2019 Type: Cement Grinding Mill ... Phone: +233 (22) 204 226 (Tema Head Office) Web: heidelbergcement. Wikipedia: HeidelbergCement ...

In addition of the main purpose to increase the efficiency of cement grinding process (increase mill output and reduce grinding cost), some cement grinding aids are also formulated to provide important strength gain effects on the final cement product Cement grinding aids that provides these kinds of "extra" properties are called as Cement ...

CEMEX is a global leader in the building materials industry. View our company profile, investor reports, sustainability focus and much more.

Vertical roller mills for cement grinding. Case Study: New 10,000tpd line 5 at Yanbu Cement. Implementation of the Messebo Cement expansion project. Cemtech Europe 2011 (2 videos ) Mikhail Skorokhod Eurocement. A review of the Polish cement industry. Cemtech Europe 2010 (2 videos )

The new Mill Audit Expert (MAE) software: Some examples of axial tests and possible causes of malfunction. Advertise with us. Axial test Interpretation: The Art Of Sharing and...Imagination. The Cement Grinding Office. Our reference list A series of real examples are exposed and interpreted. We also prove the impossibility of automating ...

important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media . Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills

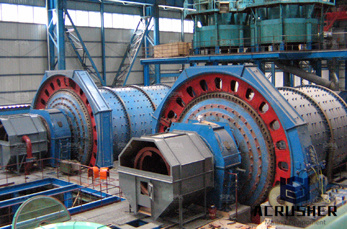

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations .

Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report™, 12th Edition ...

grinding of raw materials, coal (if used as fuel) and cement; o The single biggest consumer of electricity is the cement mill, which consumes upward of 25 kWh / t of cement ground.

WhatsApp)

WhatsApp)