grinding cylinder stone

grinding stone cylinder Newest Crusher, Grinding Mill ... Cylinder Grinding Stones on . Stones: Cylinder Grinding manufacturers, service companies and distributors are listed in this trusted and comprehensive ...

WhatsApp)

WhatsApp)

grinding stone cylinder Newest Crusher, Grinding Mill ... Cylinder Grinding Stones on . Stones: Cylinder Grinding manufacturers, service companies and distributors are listed in this trusted and comprehensive ...

welcome to rmc engine rebuilding equipment For over 50 years, RMC has imported cylinder boring mills, surface mills and crankshaft grinding machines from some of the best factories in Europe.

Product Description: Qualtech Products Industry Hydraulic Three Roller Mill is a production grinding machine at industrial scale designed and engineered for milling and wet grinding of a wide range of materials from medium to high professional Hydraulic Three Roller Mill finds its production application in the industrial fields of paints, inks, toners, lubricants ...

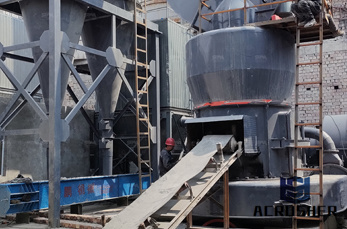

Ball mill is the key equipment for deep grinding of materials after primary crushing. It is widely used in cement, silicate products, new building materials, wearresistant materials, fertilizers, ferrous and nonferrous metal mineral processing and glass ceramics industries.

Ceramic Ball mill [ Capacity ]: –90 t/h [ Applicable Material ]: Dry ball mill is an important equipment to grind materials which is widely used in powder making production line including cement, feldspar, gypsum, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc.

Grinding cement in ball mills. The principle of the ball mill operation is simple: it consists of a rotating drum and grinding media (cylinders, balls etc). The material is placed into the drum which starts rotating. The grinding media and the substance both come in circular motion and at a certain point drop from the walls the bottom of the drum.

1) Ball mill is an efficient tool for grinding many materials into fine powder. 2) The ball mill is used to grind many kinds of mine and other materials, or to select the mine. 3) Ball mill is widely used in building material, and chemical industry. 4) There are two ways of grinding, the dry way and the wet way.

Large wet ball mill called wet ball mill, ball mill is a kind of common equipment, the production process can be continued, using special rolling bearing as the support structure of the cylinder, run more smoothly, the energy saving effect is more obvious, is the main ore dressing equipment grinding production line, which belongs to

Raymond Mill YGM Grinding Mill MFW Grinding Mill HGM MicroPowder Grinding Mill Grinding Ball mill Ceramic Ball mill DMC pulse dust collector Powder Classifier Learn more>> Ore Benefication Equipment. Energysaving Ball Mill Flotation Machine Spriral Classfier Agitator Rotary dryer ThreeCylinder Drye Wet Pan mill Gold Concentrator Learn more ...

Aug 03, 2016· Under the same production conditions, production capacity of grid mill is larger than overflow mill''s. Both ends of the cylinder body adopt rolling bearing instead of .

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

Tube mill is a cylinder body loaded with a certain number of different grades of steel balls as the grinding medium, dry or wet grinding of various ores and other grindable materials, can be open circuit grinding, but also closed circuit grinding. It is the key equipment for grinding after the material is .

Arrastra, simple mill for grinding and pulverizing (typically) gold or silver ore. Roller mill, an equipment for the grinding or pulverizing of grain and other raw materials using cylinders; Stamp mill, a specialized machine for reducing ore to powder for further processing or for fracturing other materials

The DYNO ®MILL KD disc mills are available with grinding chamber volumes from to 600 litres and are suitable for practically all types of grinding media. The production mills can be operated with grinding bead diameters from to mm.

Ball mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Besides, it is mainly applied in many industries, such as ferrousnonferrous metal mine, coal, traffic, light industry, etc.

The type of mill also can affect the selection of grinding media. Ball Mills use very large media while Attritors employ media ranging in size from 1/8" to 1". Horizontal mills require much smaller media, as small as mm to 2 mm. To read detailed specs and submit a quote, click here for our metallic media or here for our nonmetallic media.

to the particle size of the grinding material, the material is loaded into the cylinder by the hollow shaft of the wet grid ball mill feeding end. When the ball mill cylinder rotates, the grinding body acts on the cylinder liner due to the action of inertia and centrifugal force and friction. It is carried away by the cylinder.

Qualtech Products Industry Digital Three Roller Mill is a production wet grinding production machine at industrial scale designed and engineered for milling and wet grinding of a wide range of materials from medium to high viscosity. This professional Digital Three Roller Mill finds its production application in the industrial fields of paints ...

Cement Production Line. Cement production line is the production line composed of a series of cement production equipment, mainly involving crushing, prehomogenization, raw material preparation and homogenization, preheating and decomposition, sintering of cement clinker, cement grinding and packing and so on.

The 2080 production mill is capable of a 2,500 lbs. per hour feed rate of normal density mineral. It has a 9 hp motor with 19,700 lbs. max. force. The VKE 2080 mill uses virtually any type of grinding media available; rods, cylinders, balls, hex cylinders, etc. in steel, stainless steel, ceramic or zircon.

Industrial Ball Mills use horizontal rotating cylinders that contain the grinding media and the particles to be broken. The mass moves up the wall of the cylinder as it rotates and falls back into the "toe" of the mill when the force of gravity exceeds friction and centrifugal forces.

Limestone Grinding Mills to Supply 200~325mesh limestone . Through crushing and fine grinding, raw materials . decades in mineral material grinding equipment RD and . requirement for cement additive production.

Cement Ball Mill Cement Grinding Mill Cement Grinding Plant, Find Complete Details about Cement Ball Mill Cement Grinding Mill Cement Grinding Plant,Cement Ball Mill,Cement Grinding Mill,Cement Grinding Plant from Mine Mill Supplier or ManufacturerGongyi Derui Machinery Co., Ltd. ... Energy Mineral Equipment > Mining Machinery > ...

Proportioning Equipment And Grinding Mill czeueu. Proportioning Equipment And Grinding Mill Mill (grinding) Wikipedia Like ball mills, grinding (steel) roller mill, an equipment for the grinding or pulverizing of grain and other raw materials using cylinders; Stamp mill, [24/7 online] Unused Grindingequipment For Sale amking

WhatsApp)

WhatsApp)