Media charge in ball mill in cement fectory. YouTube

Feb 11, 2019· Production at Ramco Cement Plant in India Duration: 3:49. BEUMER Group TV Recommended for you. 3:49. Ball Mill || Principle construction Working and use of Ball Mill | ...

WhatsApp)

WhatsApp)

Feb 11, 2019· Production at Ramco Cement Plant in India Duration: 3:49. BEUMER Group TV Recommended for you. 3:49. Ball Mill || Principle construction Working and use of Ball Mill | ...

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

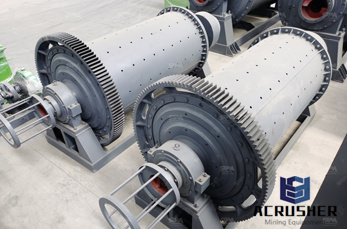

Cement ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and nonferrous metal dressings, and glass ceramics industry. As for types of cement ball mill, there are normal cement ball mill and superfine cement ball mill.

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry. In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated ...

Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

Coal ball mill electrics are for 50hz used 300 tpd white cement plant fl kilns and mills 60hz 32m x 7m polysius dry ball mill 800kw 50hz please inquire 24m x 11m polysius double rotator cement mill 700kw 50hz hie separator ball mill parts fls symetro tsfp2160b gearbox 6700hp rpm get a quoten. More Details Cement Directory Ball Mills

Industrial ball mills made available by us are heavy sheet fabricated using qualityapproved mild steel stainless steel. These ball mills are used to grind materials into extremely fine powder. Our ball mills are perfect for cement plants. Three types of ball Mills we re manufacturing: – 1. Raw materials mill 2. Cement (Clinker) mill 3 ...

Cement Plant Machinery MUSHTAQ SONS, 300 TPD Used White Cement Plant, FL Kilns and Mills, 60Hz ... 14'' X 38'' Cement Ball Mill, Central Gearbox Drive, 3235kW 50Hz X ... CPU Gear Unit The highperformance gear unit to drive your ball mill ..., The standard for central driven ball mills today, our MAAG® CPU Gear drives ...

cement plant ball mills parameters cement plant ball mills flowagency flow of material in ball mill in cement plant Ball mill ore crusher price the free encyclopedia The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for Read more cement plant equipments manufacturer and .

Photos Of Ball Mill In Cement Plants Henan Mining . Cement Plant Raw Mill Of Type Attic. A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball.

Ball mill is the cement crushing equipment in the cement plant. Compared with open circuit ball mill, the closedcircuit ball mill has high efficiency, high output, low cement temperature, and good comprehensive benefit. It is the best choice for a cement plant.

Apr 21, 2017· Ball mill for cement making plant, ball mill works principle, China Ball mill Duration: 2:29. Eric Zhang 2,625 views. 2:29. Language: English Location: United States

Subscribe to International Cement Review. 12 issues of the leading cement industry magazine, your choice of complimentary handbook, plus unlimited access to News, Articles and HD Videos. £ 205 / US 315 / EUR 260

Nov 10, 2017· Cement mill se Judi jankari aur adik jankari pane के लिए हमारा चैनल लाइक करें और सब्सक्राइब ...

Energy Efficiency And Saving In The Cement Industry. Presses tube mills ball mills and conventional or highefficiency separators IEA 2009. Although cogeneration of steam at a cement plant is possible cement plants typically require little steam and are located in isolated areas where markets

cement manufacturing, ball mill, rotary kiln, cement mill . Mills belong to a class of equipments that accomplish comminution of materials in the fine range There are two types of mills which are mostly used in cement plants for grinding raw mix viz Ball mills and VRM Ball mills Ball mills are essentially fine grinding units capable of grinding material to a fineness say 84% passing 90 ...

Cement mill . A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills . The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine ...

Rotary Kiln Cement Plant . The rotary kiln has an important role to play in the cement manufacturing process taking place in the cement plant. At Technomart, we specialize in manufacturing efficient and performanceoriented rotary cement kilns for successful completion of cement production.

Sourcing Guide for Cement Ball Mill: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: ball mill, milling machine, grinding mill.

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

Ball Mill Rpm For Rawmill Cement Plant. Ball mill drive motor choices directly connected to the mill torque tube since the speed of these motors is extremely slow 15 rpm north america and with mills above 6000hp this study began with a decision by the monarch cement company to add a new cemen

Cement mill Wikipedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills .... Large balls are used at the inlet, to crush clinker nodules (which can be over 25 mm in diameter).

Grinding Media Ball Mill Ball For Cement Plant Buy Ball. Grinding Media Ball Mill Ball For Cement Plant,Find Complete Details about Grinding Media Ball Mill Ball For Cement Plant,Ball Mill Ball,Grinding Ball,Ball Mill Ball from Mine Mill Supplier or ManufacturerXi''an Desen Mining Machinery Equipment Co., Ltd. /5

We provide ball mill equipment for cement plant, power plant, mining industry, metallurgy industry, etc. Ball mill can grind a wide range of materials, with enough continuous production capacity, simple maintenance. Capacity range from 5t/h to 210t/h. The feeding size is less than or equal to 30mm.

WhatsApp)

WhatsApp)