scatter plates in rotary drum dryer – Zhengzhou Taida ...

Diverse scatter plate device in rotary drum dryer. 1. Raising material scatter plate device, apply to drying large block and sticky materials. 2.

WhatsApp)

WhatsApp)

Diverse scatter plate device in rotary drum dryer. 1. Raising material scatter plate device, apply to drying large block and sticky materials. 2.

This professional reference book will be the first comprehensive book in many years that treats all engineering aspects of rotary kilns, including a thorough grounding in the thermal and fluid principles involved in their operation, as well as how to properly design an engineering process that uses rotary kilns. Chapter 1: The Rotary Kiln ...

Our industrytested sensor technology and patented algorithm reduce moisture content variation – increasing production, lowering energy consumption and improving product quality. "Insidethedryer" SoftSensors are rugged, reliable and accurate. Our technology pays for itself within 3 6 months, providing substantial benefits over the long term.

1 Fundamentals of Energy Analysis of Dryers Ian C. Kemp Introduction Dryingisighlyenergyintensiveprocess,accountingfor10–20%oftotalindustrial energy use in most developed countries. The main reason for this is the need to supply the latent heat of evaporation to remove the water or other solvent. There are

Oct 31, 2008· Trying to build a dryer to dry fuel for a BioMizer BioDust burner. Trying to build a dryer to dry fuel for a BioMizer BioDust burner ... Home made sawdust dryer prototype testing .

1 Fundamentals of Energy Analysis of Dryers Ian C. Kemp Introduction Dryingisighlyenergyintensiveprocess,accountingfor10–20%oftotalindustrial energy use in most developed countries. The main reason for this is the need to supply the latent heat of evaporation to remove the water or other solvent. There are

THE ROTARY DRYER HANDBOOK FEECO International was founded in 1951 as an engineering and manufacturing company. We quickly became known as the material experts, able to solve all sorts of material processing and handling problems, and now

areas that a kiln operator must evaluate in selecting a kiln burner. , with over half a century of experience in designing and manufacturing rotary kilnbased thermal processing systems, has the technical expertise and capability to provide rotary kiln operators with a kiln burner system that best meets their requirements.

Pillard RotaFlam ® is a leading rotary kiln burner for non ferrous minerals pyroprocessing and iron ore pelletization industries.. Thanks to its patented principle, the Pillard RotaFlam ® perfectly matches the combustion specific requirements of each unique process.. Applications. For calcinations and reduction processes, such as quicklime, dolomite, pulp paper lime recovery, expanded clay ...

Rotary Kiln Processes Because rotary kilns simply serve as a vessel to cause a chemical reaction or phase change, as mentioned, there are many types of processes that they can be used for. Below is an overview of some of the processes that are commonly carried out in a rotary kiln .

arrangement of the burner system to provide the necessary O2 for efficient combustion and flame orientation. It must be noted that oxidizing conditions in the burning zone that limit SO2 emissions are favorable for the generation of nitrogen oxides (NOx) in the rotary kiln. Changing raw materials may also reduce sulfur dioxide emissions.

IQS Directory provides a detailed list of rotary dryer manufacturers and suppliers. Find rotary dryer companies that can design, engineer, and manufacture rotary dryers to your specifications. Peruse our website to review and discover top rotary dryer manufacturers with .

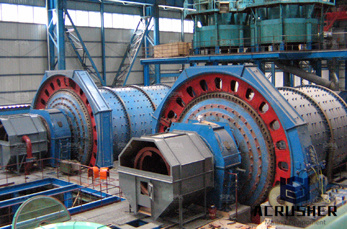

Rotary dryers consist of a rotating cylindrical shell that can be horizontal or slightly inclined. In a rotary dryer the heat transfer mechanism can be either direct or indirect. Directheat rotary dryers are more common than indirectheat rotary dryers. Shown here is a rotary dryer getting installed.

Oct 18, 2013· The burner flame provides the heat required for the vaporization of the water... Rotary kiln reactors are frequently equipped with an axial burner with which solid burden material is directly heated. ... Influence of particles falling from flights on volumetric heat transfer coefficient in rotary dryers and coolers, Powder Technology, 59 (1989 ...

Heat exchange in a rotary kiln may be by conduction, convection and radiation, in descending order of efficiency. In lowtemperature processes, and in the cooler parts of long kilns lacking preheaters, the kiln is often furnished with internal heat exchangers to encourage heat exchange between the .

burner is installed at the downhill or discharge end of the kiln where fuel is burned to form an approximately cylindrical flame. Heat transfer from this flame and the hot combustion gases that flow up the kiln dries, heats, and calcines the counterflowing lime solids. Rotary lime kilns in the pulp and paper

THE ROTARY KILN HANDBOOK FEECO International was founded in 1951 as an engineering and equipment manufacturer. We quickly became known as the material experts, able to solve all sorts of material processing and handling problems, and now serve nearly every industry, from energy and agriculture, to mining and minerals.

This chapter provides an introduction to rotary kilns as an alternative to other unit operation devices. The history and evolution of the rotary kiln and some processes that have found applications over the years are presented. The design and operation of rotary kilns have undergone a systematic evolution since the days of the ancient Egyptians.

This handbook gives an overview of the rotary kiln design process, chemical thermal analysis as well a basic background on rotary kilns much more. This handbook gives an overview of the rotary kiln design process, chemical thermal analysis as well a basic background on rotary kilns much more. ...

characteristics of the final product. This handbook reviews many types of dryers and provides guidelines for their selection. Certain types of commonly used dryers are reviewed in detail. Since drying is an energy intensive operation, this handbook also provides information on techniques to improve efficiency. APV Dryer Handbook 12/6/00 10:52 ...

method to heat a rotary kiln from cold start through to main fuel firing. A key to a safe kiln warmup is the ability to provide a stable flame for an effective and controlled heat release profile. The HeatSafe Burner (HSB) design is based on our proven OptiMix™ integrated kiln burner design, which is in operation in over 100 rotary kilns ...

1 The Rotary Kiln Evolution and Phenomenon 1 The Rotary Kiln Evolution 1 Comparison of the Rotary Kiln with Other Contactors 4 Types of Rotary Kilns 7 Wet Kilns 9 Long Dry Kilns 9 Short Dry Kilns 10 Coolers and Dryers 10 Indirect Fired Kilns 12 2 Basic Description of Rotary Kiln Operation 15 Bed ...

Rotary cascade dryers have the feed materials pass through a rotating cylinder together with a stream of hot gas. Spray Dryers Spray drying involves the atomization of feed to a spray of droplets which are contacted with hot air in a drying chamber.

LimeLine lime kiln technology is the best choice for efficient and reliable lime ... Modern and proven ANDRITZ technologies for lime reburning include the LimeKiln with a LimeFlash dryer, a LimeCool cooler, and a LimeFire burner. These systems are the result of many years of experience and a high level of expertise in providing energyefficient ...

WhatsApp)

WhatsApp)