(PDF) DESIGN AND FABRICATION OF MINI BALL MILL .

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the ...

WhatsApp)

WhatsApp)

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the ...

One of the representatives of this kind is the ball mill whereby the feed is vigorously mixed in a vessel containing free spherical bodies ... Size reduction by mechanical actions, ... Shear shredders used in MSW processing are usually the twoshaft design in order to avoid excess size reduction.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

Click to request a ball mill quote online or call to speak with an expert at Paul O. Abbe® to help you determine which design and size ball mill would be best for your process.

Pin mill is a kind of milling equipment that can break up cellular materials selectively without damaging the starch granules. It consists of two horizontal steel plates with vertical projections arranged in concentric circles on opposing faces and becomes more closely spaced towards the periphery. Pin mill...

2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP Ballmill scale up (Bond''s Law)Data: zBond work index w i zFeed D f and product d size (both 80% cumulative passing) Result: The specific grinding energy w Mill power draw P = wT, where T the mill capacity Mill dimensions (from Tables or charts)

a mechanical device, generically referred to as a "mill," in which energy is imparted to a coursegrained mate rial to effect a reduction in particle size.

conditions (15%). In addition, acquired load samplings result for mill ball filling was %. Keywords: Miduk Copper oncentrator, SAG Mill, Ball Filling Percentage Introduction Semiautogenous (SAG) mills are presently one of the most widely used alternatives in the field of mineral size reduction, as a result of their comparative

design of ball mill size reduction in usa pdf. Ball Mill Application and Design Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and pharmaceuticals materials down to 1 micron or less.

Size Reduction Milling From lab/pilot to production requirements, Hosokawa Micron Powder Systems offers a complete line of size reduction technologies. Whether you call it size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply grinding, we can help.

design foundation of ball mill ball mill foundation design . Ball Mill Design Concrete Foundation Grinding Mill,Issue 1. record in the design of mining equipment. SAG mill and three 24 ft ball mills, each driven by a Standard engineering design of mill foundations relies. Obtenir le prix

Ball Mills. IQS Directory is a top industrial directory listing of leading industrial ball mill manufacturers and suppliers in Pennsylvania. Access our comprehensive index to review and source ball mill manufacturers with preview ads and detailed product descriptions.

for Accident Prevention Design for Energy Efficiency Reduce Derivatives ... Major parameters for ball milling Temperature Size and Number of the balls ... Vibration ball mills Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm ...

[Show full abstract] of size reduction methods involved in mineral processing using crushing equipments. Crushing is the first step of mineral processing where the ore/rocks from the mine site is ...

size reduction by ball mill design leasingservices . ... Particle size reduction of materials in a ball mill with the presence of ... ball mill manufacturers in usa,ball mill grinding media size. ... design of crushing ... Get Quote. Ball Mills Orbis Machinery, LLC. Ball Mills. Our combined experience in ball mill design and process ...

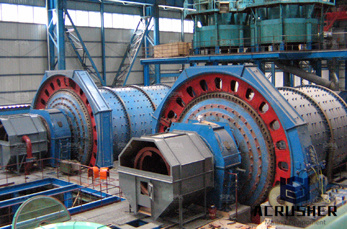

Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Mar 25, 2016· BALL MILL Principle: The ball mill works on the impact between the rapidly moving ball and the powder material, both enclosed in a hollow cylinder. Thus, in the ball mill, impact or attrition or both are responsible for the size reduction. Fig: Ball mill 13 14. Working: The drug is filled into cylinder 60% of the volume.

ball mill design filetype pdf Design Of Ball Mill Size Reduction In Usa Pdf Stone . Design Of Ball Mill Size Reduction In Usa Pdf Stone Crusher In Usa Galgotiasbschool Inlimestone crushing machine filetype pdf Hammer Mill Crushers Rock . Get Price. Buy Now. Ball Mill Design Filetype Pdf fachmonteure.

Besides particle size reduction, ball mills are also widely used for . The design of a ball mill can vary significantly depending on the . USA, 2006, 331376. 68 » Free online chat! ball mill design handbook operational manual – Coal processing . If you need more information about ball mill design handbook operational manual, .

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

design procedure for ball mill pdf patromexmx design of ball mill size reduction in usa, The runofmine ore is reduced to a particle size of less than 1 mm in the comminution circuit and concentrated using revealed abnormalities in the process and design parameters which caused high energy coarse grinding circuit, ball mill, process,

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Mar 26, 2018· Size reduction is a process of reducing large ... The ball mill works on the impact between rapidly moving ball and powder material, both enclosed in hollow cylinder. ... United States .

WhatsApp)

WhatsApp)