Pulverizers 101: Part I POWER Magazine

Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal size, moisture content, and...

WhatsApp)

WhatsApp)

Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal size, moisture content, and...

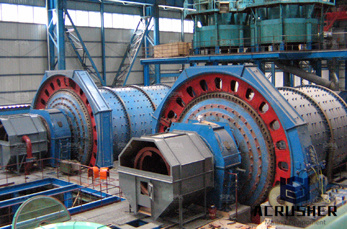

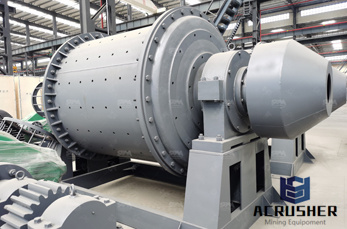

Types of coal pulverizers. Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills. A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

Pulverizers 101 Part I Power Magazine, A typical mps89 pulverizer found in many coalfired power plants on the left is a typical alstom power mill on the right an mps89 of similar capacity air emission regulations are Coal Mill Pulverizer Vertical Ball Mill For Power Plant

pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. coal mill operation in power plant Get Price

Vibrating screen feeder for coal pulverizer mill rock. alstom power plant coal grinder pulverizer 25700 XSM is a leading global manufacturer of crushing and milling equipment alstom power plant coal grinder pulverizer 25700XSM also supply individual alstom power plant coal grinder pulverizer 25700 crushers and mills as . More Details

Coal feeders provide coal to the coal pulverizers (mills) where the coal is pulverized and dried. Dryer coal is easier to pulverize, and less mill power is needed to achieve the same coal fineness. Additionally, with less fuel moisture, more complete drying of coal can be achieved in the mill. This results in increased mill exit temperature ...

A 350MW coalfired power plant in the southwestern experienced one of these events without a procedure in place. In this case, operators had run the 1D pulverizer for approximately 36 hours ...

Nov 09, 2012 pulverizer/mill system: pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill.

coal mills in power plant Villa Marina. In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers ...

Coal mill pulverizer in thermal power plants pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill.

RingRoll (BowlMill) and BallRace Mills comprise the majority of coal pulverizers currently in service at power generating facilities. Figure 3 shows a cutaway of a RingRoll type coal pulverizer. In this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a worm gear drive.

Sep 01, 2009· Primary air flow transports the pulverized coal through the mill, dries the coal for optimum combustion, and maintains coal circulation within the pulverizer. Raw coal from the feeder is fed through a downspout in the center of the pulverizer and .

558S mills commenced. Atrita Pulverizer Design The Atrita mill is an attrition type, high speed and compact designed pulverizer. For over 70 years, the Atrita mill has been used for coal firing boilers to pulverize a wide range of fuels including eastern and midwestern bituminous coals, subbituminous coals, lignite and delayed coke. There are ...

Coal mill pulverizer in thermal power plants. Nov 17, 2012 pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. Send Inquiry

Holmes Coal Pulverizers . 28 · coal mill pulverizer in. Holmes Coal Pulverizer w Sample Container Auger Feed 220V 50Hz Holmes Coal Pulverizers are benchtype units that perform well in reducing coal or coke from No 4 to No 60 sieve size Models are available with manual or auger feed All units are constructed of painted steel and cast iron and have onepiece balanced rotor with hard coated

Coal Pulverizers. The purpose of this code is to establish procedures for conducting performance tests to determine: Capacity, Fineness of product, Raw coal feed, Grindability, Moisture, Sizing, Power consumption and Effect of changes in raw coal Characteristics on product fineness, pulverizer,...

Hammer mill coal crusher YouTube. Sep 22, 2009· The above given configuration is a unique machines. We hope that you will find all qualities which you are looking in Coal Crushers. Coal Crushers is used to shape the coal for using of coal ...

A coalfired power station or coal power plant is a thermal power station which burns coal to generate power stations generate over a third of the world''s electricity but cause hundreds of thousands of early deaths each year, mainly from air pollution.. A coalfired power station is a type of fossil fuel power coal is usually pulverized and then burned in a ...

Aug 18, 2018· Major components of pulverizer plant : Bunker Feeder Coal mill Primary air fan Thermal power plant engineering | pulverized coal fired boiler ... Coal Fired Power Plant Duration: 12:24. Marcel ...

Wisconsin Electric''s Pleasant Prairie Power Plant (P4) is a baseloaded unit that burns lowsulfur, PRB subbituminous coal. A rotary car dumper unloads coal from rail cars into coal hoppers.

Nov 17, 2012· COAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in the cement industry.

Coal mill pulverizer in thermal power plants. pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill.

Pulverizer Power Plant Kids Who Code. Coal mill pulverizer in thermal power plants SlideShare. pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. types of coal mills in a thermal power plant. Get Price

Mar 25, 2017· How Vertical Grinding Mills Work (Coal Pulverizer Example) Duration: ... 14:39. LUM Series Ultrafine Vertical Roller Mill Duration: 3:07 ... Steam Power Plant Running on Coal Animation ...

WhatsApp)

WhatsApp)