Maintenance Of Cement Coal Mill

maintenance of cement coal mill Crusher In Africa. Limestone Grinding Plant in Belgium. As the finished product is for a paper making company, our buyer from Belgium needs a mill .

WhatsApp)

WhatsApp)

maintenance of cement coal mill Crusher In Africa. Limestone Grinding Plant in Belgium. As the finished product is for a paper making company, our buyer from Belgium needs a mill .

The power ingesting of a grinding process is 5060% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

Cement Plant Operations Handbook 5th Edition 16 SAMPLE 7. Maintenance 115 1. Failure Modes – 2. Computerised Maintenance Management Systems – 3. ReliabilityCentred Maintenance – 4. Maintenance Cost Management – 5. Maintenance Organisation – 6. Role, Planning and Control – 7. Mobile Equipment Maintenance 8. Environment and Pollution ...

coal mill vrm process operation manual instructions. Coal mill, VERTICAL ROLLER MILL OPERATION MANUAL,, vertical roller mill operation manual for coal mill Working Of Vertical Raw Mill In Cement Plant, . More; DiplIng Th Frland, DrIng KH Zysk, Loesche,

The energy consumption by the cement industry is . and vertical roller mills are used. Coal . in the table below for a cement plant operating at 75 kWh .

Similar to the ring and ball mill, the vertical spindle roller mill uses large "tires" to crush the coal. These mills are usually found in utility plants. Raw coal is gravityfed through a central feed pipe to the grinding table where it flows outwardly by centrifugal action and is ground between the rollers and table.

Coal Crushing Plant with Capacity 50 . manual conveyor belt cema pdf . ball mill Barite crushing plant Barytes Crusher Cement Mill coal crusher coal crushing . large capacity coal crushers Gulin provide the large capacity coal crushers solution case for you. . two stage gearbox for a coal mill grinder moisture meter for crushed coal ...

Coal Mill: Mill Bag filter jamming. Kiln Fluctuating Free lime in clinker. ... Such type of problem is quite common in cement plants and are responsible for daily kiln disturbances, mill feed variations and higher heat, power, grinding media, refractory consumptions in cement plant. ... maintenance, weak feed rate control for various input sizes.

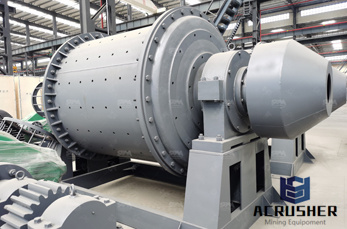

Coal business in Indonesia to grow quite good and has a lot to draw some big investors from countries in europe and asia to invest in coal mining business in Indonesia. An Introduction of Coal Mill Publisher: canales Coal Mill is major equipment of cement plant and used for drying and grinding coal. Introduction to Various Grinding Mills in Mining

Coal mill erection schedule ximit what is erection of coal mill fan coal mill errection schedule 4FT Standard erection for process fan in cement plant mining crusher for sale 17 Apr 2013 ppt Chat With Sales vertical coal mill erection procedure Get A Free Quote. Materials; Coal Mill Study Ethiopia Alianzcanineitaliait

Plant Operations. The Cement Plant Operations Handbook Sixth Edition Posts Related to types of coal in cement plant », petcoke for cement kiln pdf », cement rotary kiln waste. cement plant operations handbook on ball mill. cement ball mill maintenance pdf, grinding and blending in wet process of cement, ccr jobs in cement plant.

Coal Mill In Cement Plant Maintenance Manual cement grinding mill... Get Price. Ball Mill Maintenance Installation Procedure 911 Metallurgist. Allowable bearing pressure between concrete footings and the soil ... We recommend a mixture of 1:2:3 for ball mill and rod mill foundations. ... The drawing also carries special instructions as to ...

Maintenance of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job. The failures of these equipments have led to high maintenance and operation costs. Coal handling plants of Thermal Power Generation House have focused on the key measures of Plant study carried of maintenance of CHP,

crushing roller mill manual maintenance pdf. Loesche Coal Mill Operation And Maintenance Pdf ... Repair manual for extec c12 jaw crusher at Marks Web of ... vertical roller mill model trmk ; ... Home » Cement Crusher » loesche vertical roller mill for cement plant. ... Hard Coal, Brown Coal, Lignite, Anthracite, Petroleum and other Coke ...

Coal mill in cement plant maintenance manual. coal mill manual abwasseranlagen Manual Book Coal Mill Cement PlantHFT Heavy Coal Mill Vrm Process Operation Manual Instructions coal mill maintenance crusher machine and quarry instructions and user manual operation manual for More Info loesche coal mill

Portland Cement Plants. Safe by Design (Inherently Safe) hazardous conditions and the risk of injury and illness resulting ... Production, Maintenance, Environmental, Project, Quality, Safety ... Modern coal mill peripheral equipment ...

PMMS was created for one of the largest cement industry in Malaysia. This plant has 7 main sections consist of crusher, raw mill, core line, coal mill, cement mill, cement silo and packing plant. This plant also consists of the other section such as blower, palletizer, air and water service and fire fighting.

operation manual for coal mill. operation manual for coal mill XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (operation manual for coal mill) in more than one hundred of the worldsales of countries and regions.

intensive sectors (Thermal Power Plant, Chlor Alkali, Cement, Pulp and Paper and Iron and Steel) of Indian economy, and bringing out manuals on Good Practices for GHG Emission reduction in the selected energy intensive sectors.

Vertical Coal Mill GGBS Vertical Roller Mill Vertical Cement Mill Vertical Roller Mill Ball Mill ... Mill running without manual operation,real longterm, stable and effective automatic control, make the milling process more stable, Refinement of production operations. ... high energy consumption, high pollution cement plants will be shut down ...

Aug 18, 2018· Like us on FB, instagram twitter, LINKS down there Website : Hello dosto mera name h Ankit Ras aur le k aaya hu appk lia Mechanical...

Maintenance Roller Mills Coal Cement Grinding OK Vertical Roller Mill from Chennai IndiaMART . of Cement Grinding, OK Vertical Roller Mill, ATOX Raw Mill, ATOX Coal Mill, ATOX Mill ... Chat Now; maintenance of cement coal mill coal safety requirements in the cement industry which accounts for a very small percentage of coal usage in ...

Emissions from New Cement Kilns" [94]. Due to the small number of SCRs installed at cement plants, information on capital and operating costs for SCRs at cement plants is limited. The installation and operating costs for the SCR installed at the plant in 2013 are not publicly available at this time.

Volume 3, Issue 5, November 2013 385 Abstract— formalized by French and British engineers in the 18th This paper analyzes an existing processing management system in a cement factory in India. During the last two decades (80''s and 90''s), major technological advancements took place in design of cement plant equipment/systems. The

WhatsApp)

WhatsApp)