I203 I204 INTRODUCTION

I203 INFLUENCE OF FEED SIZE ON AG/SAG MILL PERFORMANCE 1, Isles Road, Indooroopilly, Qld 4068, Australia email :

WhatsApp)

WhatsApp)

I203 INFLUENCE OF FEED SIZE ON AG/SAG MILL PERFORMANCE 1, Isles Road, Indooroopilly, Qld 4068, Australia email :

match the specific energy required for an existing or a planned AG/SAG mill due to differences in the many operating and design variables such as feed size distribution, mill dimensions, ball load and size and grate, trommel and pebble crusher configuration. However, the "Standard" circuit specific energy

As the feed size is reduced to mm, a 62:38 mix of mm and mm balls was found to be the optimum mix. As the feed size is reduced further, less of the mm balls and more of the mm balls are required for the maximum capacity, attaining of mm balls for a feed size of mm (Fig. 6d). The capacity difference between ...

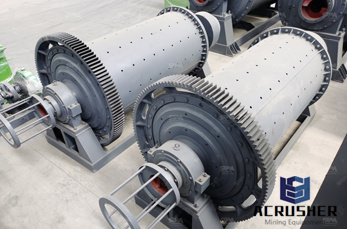

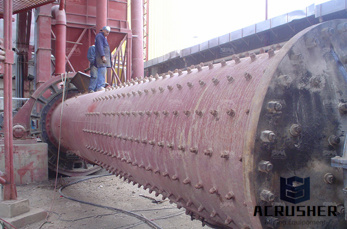

The designs of autogenous and semiautogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described.

The SAG Mill is a block added by the EnderIO mod. A machine similar to a Pulverizer or a Macerator. It is used to process resources to produce dust. It accepts energy in the form of Redstone Flux or Minecraft Joule, with an internal buffer of 100,000 RF and consumption of 20 RF per tick.

PDF | On Sep 25, 2011, Adrian Dance and others published Improvement in SAG Mill Throughput from Finer Feed Size at the Newmont afo Operation

After closedcircuit secondary crushing, the SAG mill feed 80% passing (F80) size was 25 mm to 30 mm. Installed grinding power is split equally between the two mills with the SAG mill fitted with a variable speed drive (VSD). SAG discharge screen oversize (''pebbles'' or ''scats'') was .

The feed size distribution together with the ore characteristics (hardness, lithology, alterations, etc.) are the most important factors affecting the SAG mills performance.

xG is the mill feed d80, not the circuit feed. For SAG mill, the xG value has to be determined by scalping of the full size distribution. The particles larger than the minimum pebble size (given by the pebble extraction grate opening) has to be excluded from the distribution to calculate the top ball size!

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

USING THE SMC TEST® TO PREDICT COMMINUTION CIRCUIT PERFORMANCE ... efficiency factor which represents the influence of a pebble crusher in AG/SAG mill circuits. "Coarse" in this case is defined as spanning the size range from a P80 of 750 ... energy between open and closed crushing to reach the nominated ball mill feed size. This assumes ...

stage ball mills, rod mills or AG/SAG mills when calculating power according to the Bond Third Theory method. Rod mill and AG/SAG mill products are similar and tend to be not as steep as a slope when plotted on loglog paper. This is because the particle size distribution (PSD), these mills

Minetomill optimisation: effect of feed size on mill throughput No. 48 SRK Consulting''s International Newsletter One of the most valuable aspects of blasting is the generation of very fine particles (, smaller than 12mm) that will pass through the primary mills and onto the secondary ball mill circuits, alleviating a common bottleneck.

While AG mills operate without a ball charge, SAG mills use a grinding media charge of normally 3 % 12 % for comminuting the feed material. The maximum feed size is between 200 mm and 500 mm. The AG/SAG mill is normally installed upstream of a tube mill operating in closed circuit with hydrocyclones.

2 THE APPROPRIATENESS OF THE TRANSFER SIZE IN AG AND SAG MILL CIRCUIT DESIGN ABSTRACT The AG/SAG circuit discharge P80 is now increasingly referred to as the "Transfer Size.

SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42'' () in diameter, powered by a 28 MW (38,000 HP) motor.

SINGLE STAGE SAG/AG MILLING DESIGN ABSTRACT Single stage semiautogenous / autogenous (S/AG) milling has become a common design for a variety of ore ... The feed size must be realistic as an inappropriate particle size distribution (PSD) ... The SAG mill model in the JKSimMet software has not been shown to accurately reproduce the performance

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

For example SAG mills benefit from having the finest possible top size minimisation of intermediate critical sized material and increased fines 10 mm On the other hand fully AG mills require larger rocks in the feed to act as grinding media and often do well with a bimodal feed size distribution . Live Chat

from a certain feed size to a product size as measured against a benchmark, such ... mill product size. 1 Plant relocated to Black Swan . Table 2 . SUMMARY OF COMMINUTION CIRCUITS. ... a SAG mill based circuit (P80 of 106 to 150 um) has media costs of around A1/t. Providing the ore is amenable, the use of primary autogenous milling can

Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive controller which controls mill load using direct mill weight measurement or indirectly from bearing oil pressure.

The feed size for these mills is limited to the maximum size that can be practically conveyed and introduced into the large mill feed chutes. And the product of the large AG/SAG grinding is either a finished size ready of processing, or an immediate size for further grinding in a ball mill, pebble mill, VERTIMILL® or a stirred media detritor ...

stage ball mills, rod mills or AG/SAG mills when calculating power according to the Bond Third Theory method. Rod mill and AG/SAG mill products are similar and tend to be not as steep as a slope when plotted on loglog paper. This is because the particle size distribution (PSD), these mills

Feed size effects what size is important? historically, MinetoMill has – focussed on blasting alone – generation of more fines • pass through SAG mill onto ball mill circuits • higher throughput ( 10% to 30%) • coarser grind size (possibly) fine <25mm medium 25 75mm coarse >75mm

WhatsApp)

WhatsApp)