How Are Fiber Cement Panels Created? | ArchDaily

At the start, train cars stand ready with cement and bales of fibers. A machine processes the mixture layer by layer into panels of the desired size and thickness. However, some specific ...

WhatsApp)

WhatsApp)

At the start, train cars stand ready with cement and bales of fibers. A machine processes the mixture layer by layer into panels of the desired size and thickness. However, some specific ...

Fiber cement is a popular home cladding option but that doesn''t mean it''s flawless – it''s actually far from it. There are many fiber cement siding problems you need to be aware of. Where some siding options, such as vinyl, thrive in erratic weather and require little maintenance, fiber cement tends to struggle. This can have costly ...

In this guide, we compare the benefits and costs between fiber cement panels, also called hardiplank vs vinyl siding. It''s important to consider the appearance and aesthetics, the maintenance, the impact for home resale and the cost for both types of siding.

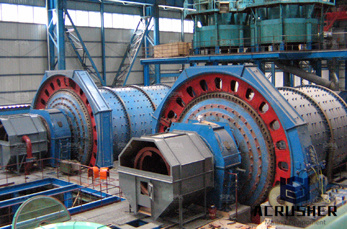

Fibre Cement Production Plants High quality, economic and flexible. ... sheeting machine filter the solids out of the fibre cement mixture. The sieve cylinders transfer the thin material layers onto the felt. The layers are dewatered ... blocks and panels, fi bre cement sheets and pipes, lime plants and

• Primed: This version allows you to paint the fiber cement siding in whatever color scheme you choose after installation. • Prepainted: With this version, the primer and paint coating process is baked onto the fiber cement panels prior to installation. The prepainted version provides a greater, longer lasting finish than any onsite ...

Without the gravel aggregate, lightweight cement cannot support the same weight as traditional cement. One method of adding strength, though, is with the addition of fibers to the mix. By mixing in fiberglass fibers, for example, you can create stronger cement, though it is still not as strong as traditional mixes.

Extremely durable fiber cement siding is resistant to moisture, fire, warping and insects. Check out our large selection of sizes and shapes.

Nichiha panels bring the look of wood, stone, brick, metal more to your commercial or residential projects with highperformance fiber cement. Read more here.

This product is made of Portland cement, wood fiber, clay and sand. The mixture produces a tough, durable siding that can be molded into different textures and profiles to .

Jun 13, 2017· fiber cement panels. With expertise, precision and craftsmanship, these elements come together to create unique panels. Cement, wood pulp and reinforcing fibers are blended along with water to form a raw mixture. The product has been scrupulously monitored for quality through the processes of winding, pressing, cutting, drying and coloring.

Fiber Cement cladding panels are ideal for ventilated, light weight facades, including wall systems, soffits, fascias, window elements, and balcony boards – just to name a few. When you select fiber cement cladding panels for your building, you benefit from numerous advantages and flexibility. Fiber Cement is Sustainable due to its durable ...

Shop fiber cement siding accessories in the siding stone veneer section of Find quality fiber cement siding accessories online or in store. ... James Hardie x 48in HZ10 HardieShingle Woodgrain Fiber Cement Shingle Siding Panel (3) Write a review. Find my store. for pricing and availability. Compare.

Allura Fiber Cement products are made with an advanced formula that resists damage from moisture, rot, hail and termite attacks. Best of all, Allura products are suitable in even the most extreme hot and cold climates and are noncombustible. Search Allura Products

The Fiber Reinforce Pronto Mix adheres over concrete and cement surfaces. perhaps, we do not recommended to apply over paint o elastomeric roof sealer. We recommended to remove the roof sealer, clean the surface and then apply the Pronto Mix. For better results and adherence on concrete roof use first Concrete Bonding Adhesive in the bear ...

Fiber Cement Board is stoutly made from a mixture of portland cement, fine silica, special cellulose fibers and selected fillers to impart durability, toughness, moisture resistance and fireproof. Fiber cement board is then cured by an autoclaving process whereby the ingredients are reacted together under the effects of superheated steam and ...

Fiber cement is usually compared to other budgetfriendly heavily processed materials like PVC or aluminum of the main reasons that architects opt for fiber cement over other lowcost alternatives is that, when detailed properly, it looks like a much more expensive product.

Composition of fibre cement siding boards and panels research citations. NichiBoard specifications indicate the product''s composition: Fiber cement panels are manufactured from a pressed, stamped, and autoclaved mix of Portland cement, fly ash, recycled rejects, and wood fiber bundles.

The term "cement" originates from the Latin word "Caementum", which signifies chopped stone. Cement describes a substance which will react chemically with water and develop into a material hard as stone. In fibre cement there is a fibre reinforcement, which contributes to making the fibrecement .

The material used to make boats or other products, although called fiberglass, is really glass fiber reinforced plasticglass fibers in a polymer matrix. If, instead of the polymer, we use portland cement and sand, the resulting material is glass fiber reinforced concreteGFRC or sometimes GRC (the Brits call it glassfibre reinforced concrete).

Fibercement siding stormed onto the scene a few decades ago and revolutionized the house siding business because it possesses the best of many worlds. It offers the look of authentic wood shiplap siding, even with lookalike textured wood grain. Unlike wood, it is fire resistant.

Fiber Cement Siding – Pros, Cons and Options. Fiber cement siding is steadily cutting into vinyl siding''s market share due to its compelling blend of paintedwood appearance, outstanding durability and very competitive price. This cement fiber siding guide will allow you to make an informed decision about whether to use this material for ...

2. Sheet Form Fiber Cement Siding. Sheet form or panel siding is available in large sheets, usually in a 5/16" basis. You can choose from a variety of different textures to .

Mar 01, 2014· Making fast setting high performance large format GFRC (Glass Fiber Reinforced Concrete) tile with Trinic''s Admix. Contact Trinic: Follow us on...

Mar 26, 2018· How to Make Fiber Cement Siding ... Typically, a mixture of Portland cement, sand and wood pulp are the key ingredients in fiber cement siding. The wood fibers reinforce the cement, forming a strong material optimal for building. The production of fiber cement siding begins with sand. Manufacturers grind silica sand into a fine powder, which ...

WhatsApp)

WhatsApp)