High Temperature Ball Mill

Chemistry lab equipment from MTI Corporation will upgrade your research laboratory. Equipment available from MTI includes diamond cut saw blades and analytical laboratory equipment.

WhatsApp)

WhatsApp)

Chemistry lab equipment from MTI Corporation will upgrade your research laboratory. Equipment available from MTI includes diamond cut saw blades and analytical laboratory equipment.

Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . ... Ball milling should be considered as a potentially attractive solution for solventfree synthesis. 21 Solvent free Onepot process Tip of iceberg .

Apr 17, 2019· Variation of the ball‐milling time is an efficient way to control the size and thickness of graphene nanosheets, as well as the level of edge defects. With an increase of ball‐milling time, superior electrochemical reactivity is imparted owing to enlarged active area and increased catalytic ability.

The ballmilled sample was annealed at low temperatures (250–350°C) to examine further the proposition that solidstate reaction is the mechanism of amorphization by mechanical alloying. A slight reaction between the Fe and B grains which were previously unreacted, probably limited to their contacting boundaries, has been detected.

The ball bearings used in most electric motors are pregreased, shielded ball bearings. Normal motor bearing operating temperatures range from 140° to 160°F. As in all bearing applications, this measurement should be taken at the bearing outer ring.

The permissible operating temperature for NBR seals is –40 to +100 °C (–40 to +210 °F). Temperatures up to 120 °C (250 °F) can be tolerated for brief periods. Typically, temperature peaks are at the seal lip. Lubricants. Temperature limits for greases used in sealed SKF angular contact ball bearings are provided in table 1.

Cryogenic milling, or cryomilling, is the process of using liquid nitrogen to lower the temperate of the material and/or the milling process. AVEKA ''s cryogenic hammer mills can typically reduce the particle size from small pellets down to the 100s of microns.

Besides materials synthesis, highenergy ball milling is a way of modifying the conditions in which chemical reactions usually take place either by changing the reactivity of asmilled solids (mechanical activation — increasing reaction rates, lowering reaction temperature of the ground powders)—or by inducing chemical reactions during ...

The synthesis is performed by solid‐state reduction reaction which occurs during room‐temperature ball‐milling of mixtures of a metal oxide (M x O y) and aluminum (Al 2y/3). A complete reduction is reached for milling times of ≅ h in a planetary mill. The crystallite sizes of alumina and metal obatined, for powders processed in a ...

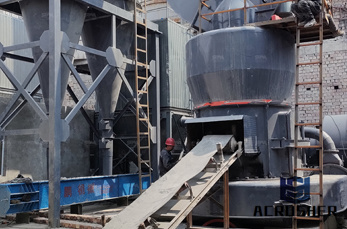

Ball mills. These are similar to cement mills, but often with a larger gas flow. The gas temperature is controlled by coldair bleeds to ensure a dry product without overheating the mill. The product passes into an air separator, which returns oversized particles to the mill inlet.

Feb 17, 2020· You must warm up the machine axes to bring the ballscrews to a normal temperature for operation. You can warm up the machine automatically by changing certain settings: Use either Settings 158160 or Settings 109112 .

The process involves extensive ball milling of boron powder for a long period of time (up to 150 h) in NH 3 gas followed by annealing at high temperature (up to 1300°C) in N 2 environment. It was suggested that a nitriding reaction was induced between boron powder and NH 3 gas due to high energy milling, resulting in metastable disordered BN ...

Jul 12, 2020· it is challenging to ball mill pure Al at room temperature because you risk to splat the metal on the balls and mill surface. cryo mill is recommended. Then, concerning the ball .

The ball mill operator can keep the temperature of the ball mill grinder in the appropriate range, prevent the overheating of ball mill in summer, and give full play to the work efficiency of the ball mill grinder. PRE Posts. To Eliminate The Hidden Dangers And Build A .

The roomtemperature magnetic properties of ballmilled strontium hexaferrite particles consolidated by sparkplasma sintering are strongly influenced by the milling time. Scanning electron microscopy revealed the ballmilled SrFe 12 O 19 particles to have sizes varying over several hundred nanometers.

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Titanium hydride with a body centred tetragonal structure was rapidly synthesized at room temperature by ball milling titanium powders under a hydrogen atmosphere. The structure evolution was monitored by xray diffraction and Rietveld analysis. Unit cell volume dilation suggests the hydrogenation process begins with the formation of a titanium hydrogen solid solution followed by the ...

UNION PROCESS, INC. 1925 AkronPeninsula Road Akron, Ohio 44313 Phone: Fax:

temperature rather than the PCB temperature. Local analog or digital temperature sensors determine temperature by measuring their own die temperature. Therefore, it is important to understand the dominant temperature conduction paths between the die of the temperature sensor and the object or environment whose temperature is to be determined.

As we all know, due to the impact of grinding media, friction energy between the grinding material and ball mill, and the energy released when the material is ground, the ball mill grinder prone to excessive temperature phenomenon, and sometimes the working environment even as high as 40, 50 degrees in .

The cold air produced by the liquid nitrogen is continuously injected into the ball mill, and absorb the heat generated by the highspeed running of the jars. So the jars filled with materials and grinding balls are always in a low temperature environment.

In autogenous milling, temperature can significantly influence the grinding efficiency, particularly if the temperature falls below about 10°C. these efficiency changes can be reduced by preventing recycle water from becoming chilled, and by thawing frozen rock before grinding.

(5) 200 gallon Ball Mills – ceramic lined, dry (1) 100 gallon Ball Mill – ceramic lined, wet (2) 60 gallon Ball Mills – ceramic lined, dry (1 with temperature control) (1) 25 gallon Ball Mill – ceramic lined, dry or wet; Jar Rolling Mills – ceramic and steel, lab scale; Dry and Wet milling capabilities; Wide variety of milling .

of the rings, balls, and cages from BluelBlack gold to blue. Temperatures in excess of 400°F can anneal the ring and ball materials. The resulting loss in hardness reduces the bearing capacity causing early failure. In extreme cases, balls and rings will deform. ''Ihe temperature rise can also degrade or destroy lubricant Common culprits are heavy

WhatsApp)

WhatsApp)