TCB Metals and Refining

Do you have value locked inside your ore concentrates? We can unlock that value and convert your ore into cash. TCB Metals and Refining, specializes in the recovery of precious metals from your ore .

WhatsApp)

WhatsApp)

Do you have value locked inside your ore concentrates? We can unlock that value and convert your ore into cash. TCB Metals and Refining, specializes in the recovery of precious metals from your ore .

The gold processing industry is experiencing change. As freemilling and oxide ores become depleted, more complex polymetallic and refractory ores are being processed, coupled with increasing pressure for stricter environmental compliance.

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

During the nineteenth century, Nevada industrialists revolutionized the milling of gold and silver ore. Nineteenthcentury millers used various techniques. Most employed mercury, a metal that readily bonds with gold and silver to form what is known as an amalgam.

Mineral Processing. If the mineralogy of the ore shows that you can separate discrete particles of the mineral you want from the gangue components of the ore, then it is possible to physically concentrate the valuable mineral and reject the rest. The easiest method for achieving this is by gravity separation.

Nov 25, 2019· Gold ore processing process and production line equipment introduction: Gold mine production line process (CIP) is a nonfiltered cyanide carbon slurry process ... Gold ore processing process and production line equipment introduction,Heyshell Games Forum

20+ items· 21 Gold Ores Processing Companies in the United States. Search or browse our list of Gold Ores Processing companies by category or location. ... Gold Ores Processing in the United States. Manta has 21 companies under Gold Ores Processing in the United States. ... City Line Gold Buyers 287 West 1st Street Mount Vernon, NY 10550 (914) ...

Gold Jigging Separator in Gold Ore Processing Line. Founded in 1986, Forui has rich experience in the production of flotation machine, gold separators including jig machine, amalgamation barrel, mercury ointment distillation tank, etc. The JT1070/2 jig separator is used in gold ores beneficiation.

Metallurgical ContentGold Leaching Processing of Arsenic OreMispickel (Arsenopyrite: FeAsS).6Leaching and Recovering Gold from Antimony MineralsStibnite (Antimony Sulphide, Sb2S2)Telluride Gold Ore ProcessingSolubility of TelluridesGold Extraction from Carbonaceous OreList Gold Refractory Process Methods Where gold is associated with arsenic, antimony, tellurium, and .

Gold ore processing process and production line equipment introduction. ... Gold ore processing process and production line equipment introduction. qizhen0809 Posting Freak. Posts: 4,666 Threads: 4,666 Joined: Aug 2017 #1., 01:38 AM . that is best for your abode, you will certainly be surprised with a great array of shutters to ...

OreMax Systems. System Objectives; System Components; System Design; Side Slope System; System Logistics; Don''t Drown The Oxygen Out of Your Leach Pad! How Drip Irrigation Works in Heap Leach Mining; Products. MaxEmitterline; MaxEmitterline Connectors; Lay Flat; Pressure Regulators; Sprinklers; Drainage Pipe; HDPE Pipe; Butterfly Valves ...

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the .

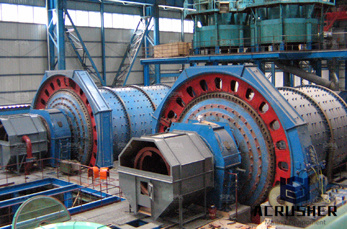

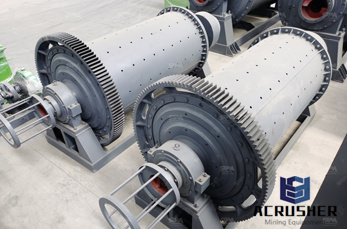

Once the ore is delivered to the mill, the grinding circuit reduces the ore to a very fine particle size (about half of the size of a grain of table salt). This is the first step in separating the gold from the rest of the rock. GRAVITY: Approximately 1/4th of the gold is recovered using gravity methods. Imagine a really big sluice box or gold pan.

Gold Cil Processing Line; Scheelite Flotation Production Line; Chrome Ore Mining Process; Nickel Ore Mining Process; Wolframite Mineral Processing; EPC. mineral grinder philippines; ball mill gold ore in egypt; provinces gold mineral processing in south africa; gold ore flotation machine flotation separator;

【Process Introduction】 Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Gold Flotation Production Line. Flotation is a method that is widely used in gold ore processing plant to process the rock gold,commonly used in dealing with highly floatable sulfide minerals containing gold ore. Flotation process can maximum enrich gold to the sulfide mineral, tailings can be abandoned directly, the cost of processing plant ...

Gold Ore Impact Flail Processing Rock Quartz Crush Mill – Gold .. Gold Ore Processing Mill Crushes Quartz and Mining Rock Ore . They will also process the gold bearing quartz rock much faster that a ball roller are . Click Chat Now

In the dressing production, due to the different types and nature of gold ore beneficiation methods used are also different, but commonly use reelection, flotation, amalgamation, cyanidation and resin slurry method, CIP adsorption, and new heap leaching gold extraction process. For certain types of ore, always using joint gold extraction process.

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Gold CIL Processing Line. Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold...

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of ...

Gold Ore Processing Production Line. Common process of gold ore beneficiation: Primary crushing – Secondary crushing – Sieving – Third crushing – Grinding – Classifying – Lower magnetic separation – Strong magnetic separation – Filtering – ore crusher is important within the mining and beneficiation method. ...

Nov 18, 2019· Gold ore processing process and production line equipment introduction color and strength. Alside insulated wpc units use the latest technology to ensure the best possible insulation performance and seal strength.

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit as well ...

WhatsApp)

WhatsApp)